COLLEGE STATION, Texas — Alongside a team of researchers from across the nation, Dr. Enrique J. Lavernia, professor in the Department of Materials Science and Engineering and the J. Mike Walker ‘66 Department of Mechanical Engineering at Texas A&M University, has discovered a refractory alloy that contradicts this trend by exhibiting an unprecedented fracture toughness at very low temperatures due to its ability to form kink bands.

According to a news release, the findings showcase that this novel class of materials can show resistance to fracture in a wider range of temperatures, broadening their real-life applications.

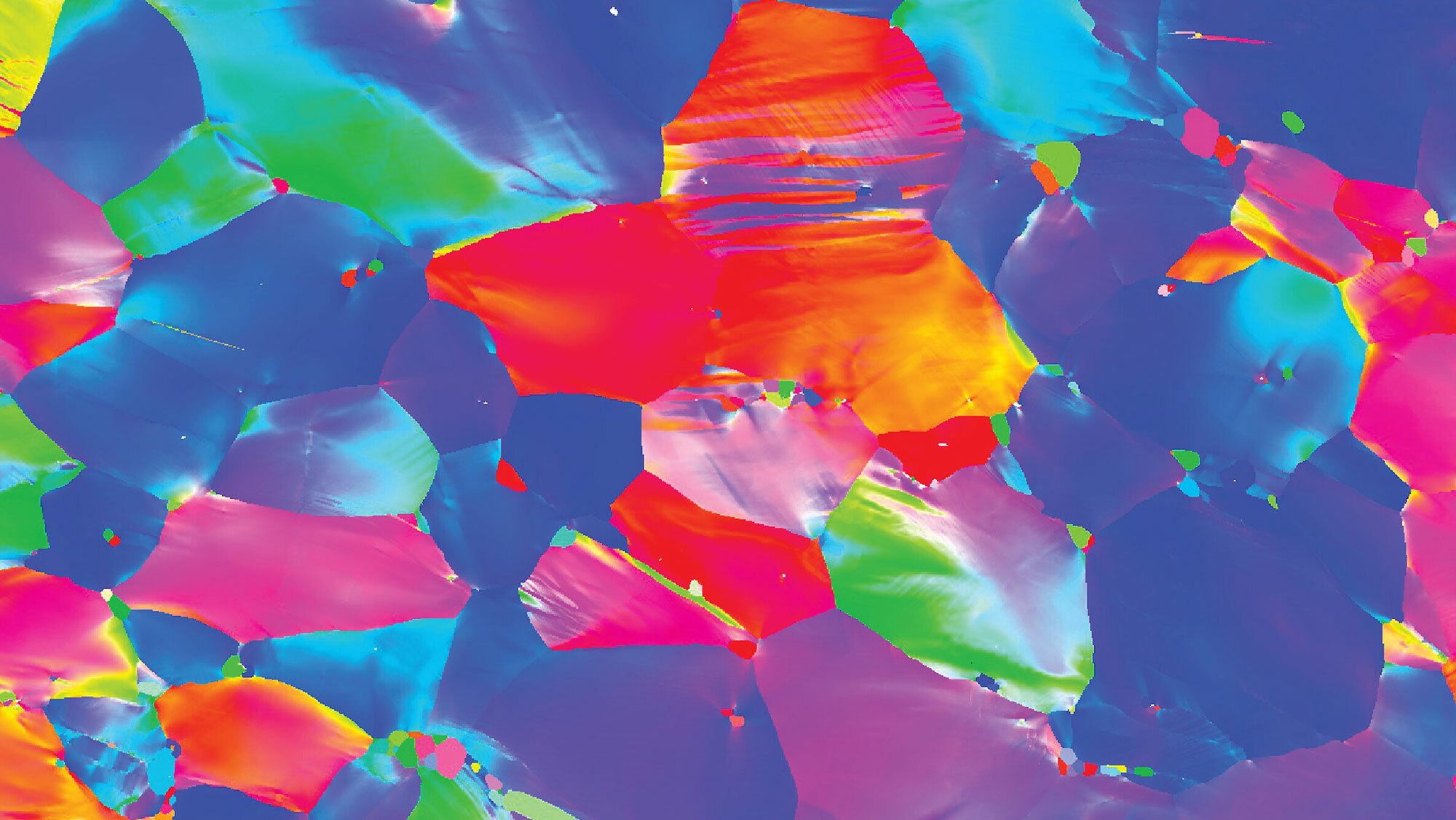

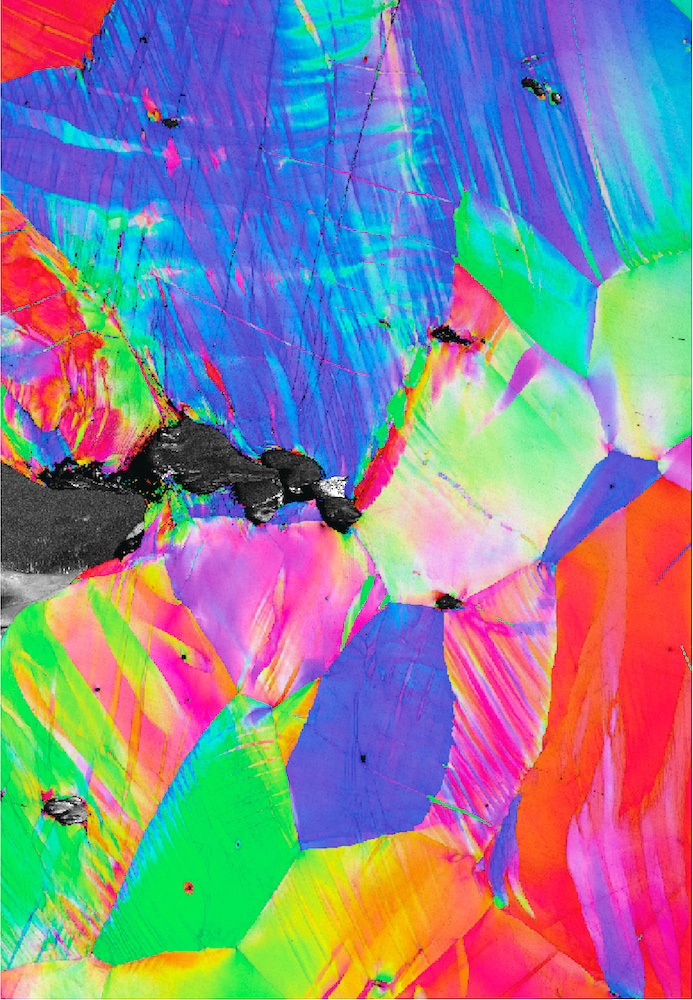

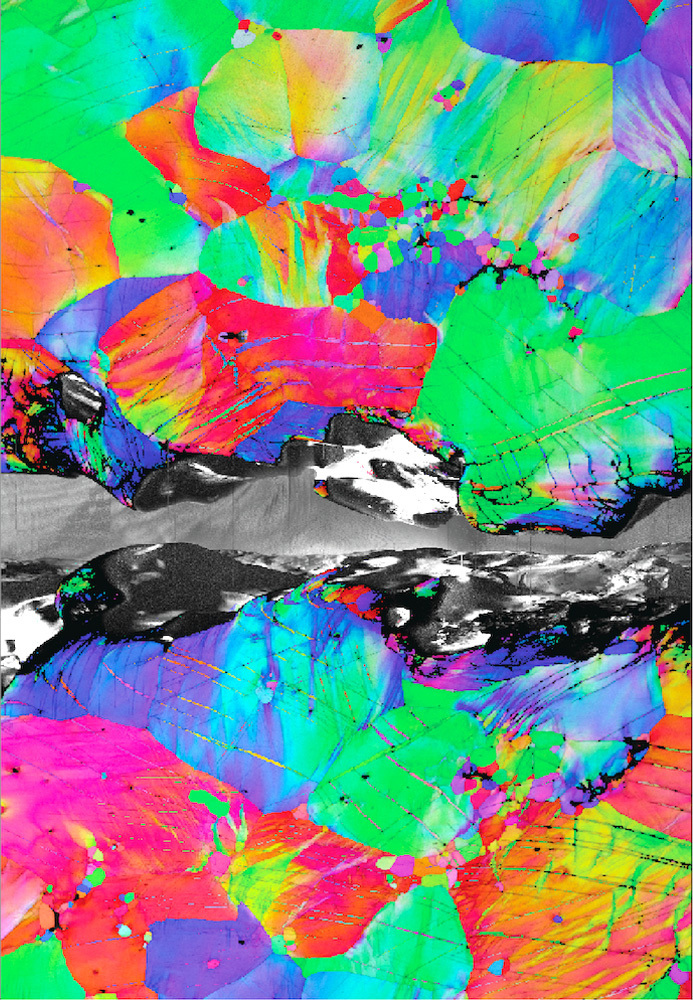

To conduct this study, the researchers used a multidisciplinary approach that involves synthesis and experiments to determine mechanical properties and detailed characterization using electron microscopy techniques to study these novel materials and their deformation behaviors.

The study investigated the mechanical properties of a refractory medium-entropy alloy made of niobium, molybdenum, tantalum and hafnium (NbTaTiHf).

To test the new alloy’s response to extreme environments, the researchers exposed the alloy to a wide range of temperatures, from 77 to 1473 Kelvin — the equivalent of – 321.07 Fahrenheit to 2191.73 Fahrenheit.

Research revealed that the alloy could retain strength and fracture toughness at these temperatures because of its ability to form kink bands. Kinks bands are deviations of a dislocation effect within a crystal structure that contain a change in the positioning of atoms. These dislocations allow atoms to slide over each other at low-stress levels on a glide plane.

The toughness of the discovered alloy is attributed to these dislocations, which promote strain hardening to form the kink bands, dispersing damage away from crack tips, researchers said.

“Contrary to a generally accepted concept, body-centered cubic refractory alloys can possess extraordinary fracture toughness across cryogenic and high temperatures that arise from the coordinated glide of edge dislocations at a crack tip, which results in complex arrays of kink bands,” said Lavernia.

This discovery of this potentially new mechanism could lead to increased applications for refractory alloys.

Source: Texas A&M University